Assembling the Guitar

To assemble the guitar the completed Rim is installed in the Universal Mold face down. The Back is then glued on. When the glue has cured the open body is then taken out and re-installed with the Back down. A thin coat of shellac is applied inside to the Sides, the Back and the (yet) unattached Top as a moisture barrier. Then the Top is glued on. Next the bindings are installed and the body sanded smooth. Then the Neck is carefully fitted to the Body and glued on. Then the Fingerboard is made, fretted and glued on. The final assembly step is the gluing of the Bridge. All these steps require great precision.

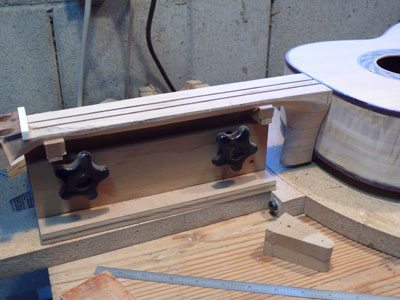

The

vertical posts of the Universal Mold are not only used to define the

outline of the guitar, they are also used to clamp the Back or the Top

to the Rim for gluing. Each posts has a screw-in threaded rod and a

larger diameter cork-padded disk that is pressed down with a wing nut

during the gluing process.

The

vertical posts of the Universal Mold are not only used to define the

outline of the guitar, they are also used to clamp the Back or the Top

to the Rim for gluing. Each posts has a screw-in threaded rod and a

larger diameter cork-padded disk that is pressed down with a wing nut

during the gluing process. Prior

to gluing the Back it is precisely positioned over the Rim, and the

positions of the bracings are marked on the kerfing. The kerfings are

then slotted to accommodate the ends of the bracings, and the bracings

are cut off to fit into these slots. This will greatly strengthen the

body.

Prior

to gluing the Back it is precisely positioned over the Rim, and the

positions of the bracings are marked on the kerfing. The kerfings are

then slotted to accommodate the ends of the bracings, and the bracings

are cut off to fit into these slots. This will greatly strengthen the

body. The

process for gluing on the Top is the same as for the back. The Top is

first aligned on the Rim to mark where the cross-braces fit into the

kerfing. Then the kerfings are slotted as shown above, and then the Top

is glued and clamped in the same way as the Back was before.

The

process for gluing on the Top is the same as for the back. The Top is

first aligned on the Rim to mark where the cross-braces fit into the

kerfing. Then the kerfings are slotted as shown above, and then the Top

is glued and clamped in the same way as the Back was before. The

lining is a strip of hardwood installed along the edges between the Rim

and the Top and the Rim and Back. Often this is made from the same wood

as the Sides, but it can also be different for color accent. In general

the lining includes several veneer strips of different color to give

the lining a distinctive look. This is called purfling. To prepare for

the lining and purfling a rabbet is

cut into the Rim along the edges of the Top and the Back as shown.

The

lining is a strip of hardwood installed along the edges between the Rim

and the Top and the Rim and Back. Often this is made from the same wood

as the Sides, but it can also be different for color accent. In general

the lining includes several veneer strips of different color to give

the lining a distinctive look. This is called purfling. To prepare for

the lining and purfling a rabbet is

cut into the Rim along the edges of the Top and the Back as shown. The

joints of the lining and purfling strips at the back inlay are tricky

and need to be done with great care.

The

joints of the lining and purfling strips at the back inlay are tricky

and need to be done with great care.

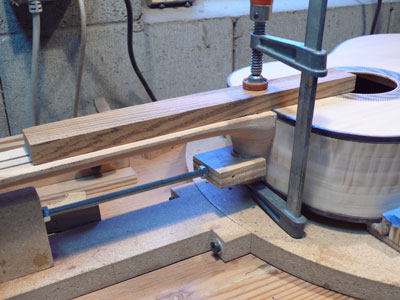

Before

the linings are

glued in they need to be shaped to the curvature of the Rim. I do this

in the bending machine, same as for the Sides. To obtain

a tight fit the linings are pressed into the rabbet during gluing. This

is accomplished using a fixture consisting of two parts, one on the top

and one on the bottom of the Body studded with nails and a large number

of rubber bands between them as shown.

Before

the linings are

glued in they need to be shaped to the curvature of the Rim. I do this

in the bending machine, same as for the Sides. To obtain

a tight fit the linings are pressed into the rabbet during gluing. This

is accomplished using a fixture consisting of two parts, one on the top

and one on the bottom of the Body studded with nails and a large number

of rubber bands between them as shown. The

Neck needs to be precisely joined to the Body. Key points in the

geometry are the Nut, the Saddle and the 12th fret. Not only do they

need to be on the centerline of the guitar, but the triangle these

points form must allow for the correct string action height. Contrary

to the Steel String Guitar the Neck of the Classical Guitar does not

contain a so-called truss rod which allows height adjustments of the

neck.

The

Neck needs to be precisely joined to the Body. Key points in the

geometry are the Nut, the Saddle and the 12th fret. Not only do they

need to be on the centerline of the guitar, but the triangle these

points form must allow for the correct string action height. Contrary

to the Steel String Guitar the Neck of the Classical Guitar does not

contain a so-called truss rod which allows height adjustments of the

neck. Once

the correct position of the neck has been established the Neck/Body fit

of the heel needs to be carefully achieved with chisels and sandpaper.

Once

the correct position of the neck has been established the Neck/Body fit

of the heel needs to be carefully achieved with chisels and sandpaper.

The

gluing and clamping is rather simple.

The

gluing and clamping is rather simple. Note

the double

carbon fiber strip in the center of the Neck which stiffens the Neck to

reduce Neck bending as a result of the string tension.

Note

the double

carbon fiber strip in the center of the Neck which stiffens the Neck to

reduce Neck bending as a result of the string tension. There

are many ways to to make the Fingerboard and to glue it to the

Neck/Body. My preferred way is to fit the unfretted Fingerboard to the

Neck/Body, then to cut the fret slots, then to install and dress the

frets and then to glue on the Fingerboard. Others glue on the slotted

and fitted Fingerboard before fretting it in place. I have also

glued the finished fretted Fingerboard to the Neck before

gluing the Neck to the Body. Each approach has its pros and cons, and I

will continue to experiment until I settle on the best approach.

There

are many ways to to make the Fingerboard and to glue it to the

Neck/Body. My preferred way is to fit the unfretted Fingerboard to the

Neck/Body, then to cut the fret slots, then to install and dress the

frets and then to glue on the Fingerboard. Others glue on the slotted

and fitted Fingerboard before fretting it in place. I have also

glued the finished fretted Fingerboard to the Neck before

gluing the Neck to the Body. Each approach has its pros and cons, and I

will continue to experiment until I settle on the best approach. The

Bridge can be glued on either before or after the Top has a finish on

it. What is more important is its precise position relative to the 12th

fret, the center point of the string length. The distance between the

front edge of the Saddle and the center of the 12th fret is the same as

the distance between the Nut and center of the 12th fret with a 2.5mm

compensation added at the Saddle. Note that the bottom of the Bridge

has a curvature to

match the Top's . Also, for the gluing process a caul is used on the

inside to allow the Bridge to be clamped against.

The

Bridge can be glued on either before or after the Top has a finish on

it. What is more important is its precise position relative to the 12th

fret, the center point of the string length. The distance between the

front edge of the Saddle and the center of the 12th fret is the same as

the distance between the Nut and center of the 12th fret with a 2.5mm

compensation added at the Saddle. Note that the bottom of the Bridge

has a curvature to

match the Top's . Also, for the gluing process a caul is used on the

inside to allow the Bridge to be clamped against.