The Neck

It

all starts with a shallow cut with a band saw across the neck blank to

create the head. Typically this is a 10 degree cut, but 8-12 degrees is

customary.

It

all starts with a shallow cut with a band saw across the neck blank to

create the head. Typically this is a 10 degree cut, but 8-12 degrees is

customary.

The

headpiece is then glued on backwards to make the angled head.

The

headpiece is then glued on backwards to make the angled head.

The

upper surface of the neck (where the fretboard will later be glued on)

is then milled flat at the appropriate thickness.

The

upper surface of the neck (where the fretboard will later be glued on)

is then milled flat at the appropriate thickness.

This

needs to be a precise operation as the neck thickness is tapered.

This

needs to be a precise operation as the neck thickness is tapered.

To

make the head the next step is to glue to the top side of the head

2 or 3 pieces of thin black and white veneer and a thicker

piece of hardwood to stiffen the head and give it

an appearance to match the other wood choices of the the guitar.

To

make the head the next step is to glue to the top side of the head

2 or 3 pieces of thin black and white veneer and a thicker

piece of hardwood to stiffen the head and give it

an appearance to match the other wood choices of the the guitar. Then a

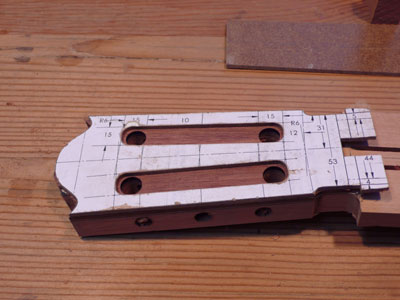

head template is glued to the top side with double-stick

tape and 4 guide

holes are drilled for the two slots.

Then a

head template is glued to the top side with double-stick

tape and 4 guide

holes are drilled for the two slots. A

pattern router bit is used to shape the inside and the outside of the

head to match the template.

A

pattern router bit is used to shape the inside and the outside of the

head to match the template. Shaping

the neck is really a sculpting task. It is very important that the

shape is "friendly" to the fingers that will play the guitar and should

be what the player expects. This shape has evolved over the history of

the instrument and needs to be closely recreated for each new

instrument. It would be easy to obtain a correct and consistent shape

using computer-controlled machinery, but for a hand-crafted guitar it

is the judgment and skill of the builder that counts. Fortunately human

eyes and fingertips are quite amazing at determining when the shape is

right.

Shaping

the neck is really a sculpting task. It is very important that the

shape is "friendly" to the fingers that will play the guitar and should

be what the player expects. This shape has evolved over the history of

the instrument and needs to be closely recreated for each new

instrument. It would be easy to obtain a correct and consistent shape

using computer-controlled machinery, but for a hand-crafted guitar it

is the judgment and skill of the builder that counts. Fortunately human

eyes and fingertips are quite amazing at determining when the shape is

right.